Concrete might look ‘all the same’, but beneath the surface lies a world of specialist mixes designed for exacting conditions, demands, and performance goals.

At Hills Quarry Products, we don’t just offer ‘standard concrete’, we supply bespoke, high-performance, and innovative concrete solutions tailored to your project’s needs.

Let’s explore some of those specialist concretes when you might need them, and real local use cases…

Types of specialist concretes and their uses

Watertight/reduced-permeability concretes

These mixes incorporate advanced admixtures and design to minimise water ingress.

Ideal for basements, retaining walls, marine works, or structures exposed to groundwater or sea spray.

Lightweight & heavyweight concrete

When optimising structural weight or requiring mass (for shielding, ballast, or vibration damping), these concretes come into play.

Hills offers heavier or lighter density mixes depending on structural or functional needs.

Fibre-reinforced concrete (steel or polypropylene)

Fibres are batched into the concrete to help control cracking (plastic shrinkage, settlement), improve durability, and enhance surface performance.

Polypropylene fibres (typically 12 mm) reduce plastic shrinkage cracking, bleeding, and improve impact resistance.

Macro fibres (lengths of 30–60 mm) can sometimes replace traditional steel reinforcement in certain structural applications, reducing labour and steel usage.

Foamed Concrete

A lightweight, flowable concrete with entrained air, used for void filling, trench reinstatement, insulating floor screeds, or filling redundant tanks and pits.

Its self-levelling, self-compacting nature helps in hard-to-access areas.

When & why you’d choose specialist concretes

-

Exposure & durability demands: In marine environments, or in structures exposed to freeze-thaw, salts, or moisture, you’ll want a watertight mix or fibre reinforcement to resist cracking and ingress.

-

Weight / density control: If you’re building something where weight is a factor (e.g., roof slab, ballasted systems) or need ballast/mass (e.g. counterweights), lightweight or heavyweight concretes are helpful.

-

Complex forms & tight reinforcement cages: Foamed or self-compacting types fill spaces where compaction is difficult.

-

Speed or site constraints: Fibre-reinforcement or macro fibres reduce need for secondary reinforcement or reduce cracking risk in fast pours.

-

Void filling or reinstatement: Foamed or flowable concretes are ideal for trench reinstatement, infill, or spaces with obstructions.

-

Cost or construction efficiency: Reducing the need for steel mesh, or cutting back on labour/time in reinforcement placement, can make these mixes attractive.

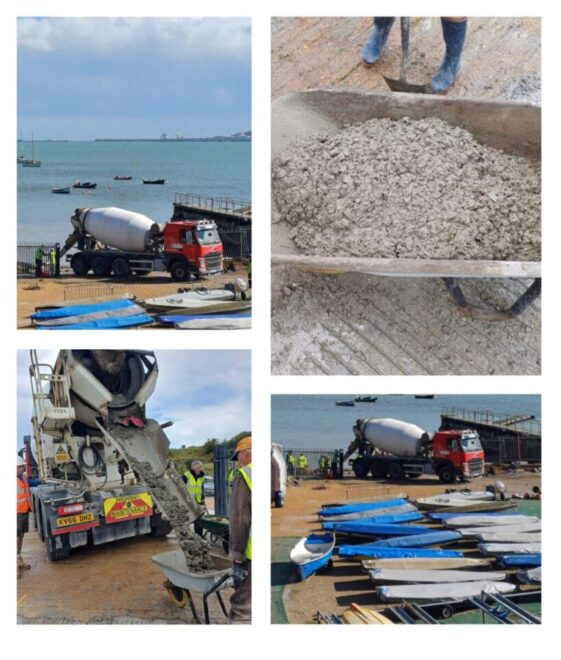

Local case study: Castle Cove Sailing Club’s new slipway

One of the best ways to see specialist concrete in action is closer to home.

At Castle Cove Sailing Club, Hills supplied a P450 concrete mix with Durus EasyFinish fibres for a new slipway into the sea. This application demanded:

-

Resistance to cracking & durability: The slipway is subject to wet-dry cycles, saltwater spray, and repeated launching of boats.

-

Toughness & longevity: The fibre reinforcement helps the structure manage tensile stresses and reduce maintenance needs over time.

-

Precision & performance: Given the marine setting and exposure, a standard mix wouldn’t suffice.

Volunteers from the sailing club have been assisting with pours, and a few pours remain before the entire slipway is complete. The project is a perfect illustration of how specialist concrete, properly engineered, makes a difference in real-world environments.

How Hills Quarry Products can help you choose the right mix

-

Technical advice & bespoke design: Hills’ team works with you to determine the right combination of mix type, fibres, density, and aggregate size to meet project specs.

-

Regional supply & logistics: Their specialist concretes (like foamed concrete) are supplied from multiple plants across their region (Wiltshire, Gloucestershire, Dorset, Berkshire, Oxfordshire).

-

Consistent quality & reliability: Even for niche mixes, the same standards, control, and delivery reliability apply.