Specialist concretes

We professionally supply a full range of specialist concretes, tailored to the exact needs of our customers and their project requirements.

Whether you’re working on a demanding infrastructure build, a bespoke architectural design, or a complex industrial application, Hills Quarry Products can provide a concrete solution that meets your specifications with consistency and reliability.

Our offering includes watertight concretes incorporating advanced admixtures for reduced permeability, lightweight or heavyweight concrete mixes for structural optimisation, and reinforced options using either steel or polypropylene fibres to enhance strength, durability, and crack resistance. We also supply concrete mixes using larger aggregate sizes (such as 40mm) for specific structural demands, as well as foamed concrete for void fill, insulation, and lightweight construction applications.

With extensive experience and a commitment to quality, our team is here to advise on the most suitable concrete type for your project. Contact our expert sales team today for technical support, bespoke mix design, and a competitive quotation tailored to your needs.

Improved water-tight concretes

Foamed concrete is a versatile and cost-effective solution for a wide range of construction applications where low density, high flowability, and excellent insulation properties are required.

At Hills Quarry Products, we supply high-quality ready-mixed foamed concrete tailored to meet the specific needs of your project, whether for void filling, trench reinstatement, or insulating floor screeds.

We deliver foamed concrete from our plants located in Wiltshire, Gloucestershire, Dorset, Berkshire, and Oxfordshire. Our team is here to help you choose the right solution and ensure smooth, hassle-free delivery to your site.

Advantages & benefits of foamed concrete are:

-

Lightweight

-

Self-levelling and self-compacting

-

Thermal and acoustic insulation

-

Cost-effective

Trench reinstatement and void filling

Hills Concrete can readily supply materials that have been developed, using high air content concrete, for use in highway construction and maintenance.

These materials may allow more rapid, reliable and cost-effective reinstatements, with less dependence on the skill and physical effort of the operators.

These materials may also offer significant environmental or practical advantages, and/or cost benefits, compared with conventional materials, including various combinations of the following:

- Speed of reinstatement and decrease in open trench times and reduced liability of returned maintenance

- Lower energy requirements during manufacture and/or laying

- Self-cementing properties to improve performance, reliability of laying and compaction

- Self-levelling or flowable, to avoid or reduce the need for compaction and to provide health and safety benefits, reducing the number of lifts

- Flow around pipes and into voids where conventional filling would be difficult

This type of concrete is also suitable for filling redundant tanks, pits and cellars.

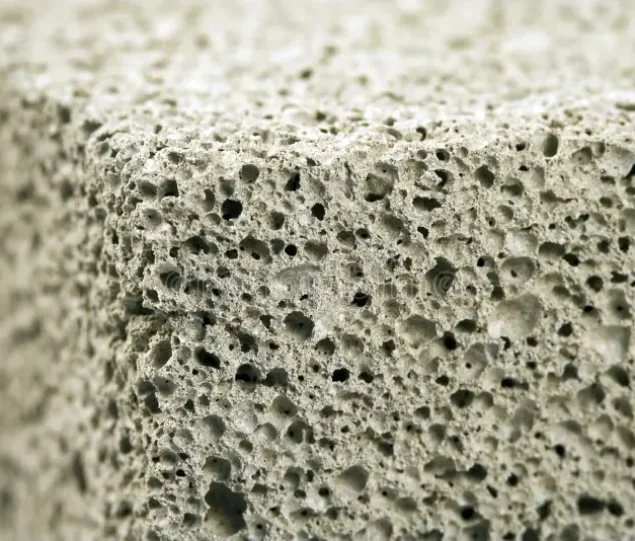

Foamed concretes

Foamed concrete is a versatile and cost-effective solution for a wide range of construction applications where low density, high flowability, and excellent insulation properties are required.

At Hills Quarry Products, we supply high-quality ready-mixed foamed concrete tailored to meet the specific needs of your project, whether for void filling, trench reinstatement, or insulating floor screeds.

Advantages & benefits of foamed concrete are:

-

Lightweight

-

Self-levelling and self-compacting

-

Thermal and acoustic insulation

-

Cost-effective

Polypropylene fibres

Hills Quarry Products has supplied a vast amount of concrete with polypropylene fibres.

These fibres are batched in the concrete to reduce the occurrence of plastic shrinkage cracking and plastic settlement, whilst enhancing the surface properties and the durability of the hardened cementitious product.

The fibres are generally in lengths of 12mm and the fibres are coated with surfactant to improve dispersion and bond.

Advantages & benefits of polypropylene fibres are:

-

Reduced plastic shrinkage cracking

-

Reduced plastic settlement cracking

-

Increased abrasion properties

-

Reduced bleeding

-

Increased impact resistance

Macro fibres

We supply concrete containing macro fibres (high-strength fibres, typically ranging from 30mm to 60mm in length) that can replace traditional steel reinforcement and improve the performance of the concrete.

This is ideal for a wide range of structural applications, delivering high tensile strength, enhanced durability, and long-term crack resistance, while reducing installation time and labour costs.

Advantages & benefits of macro fibres are:

-

Reduces need for steel mesh reinforcement

-

Improved impact and fatigue resistance in demanding environments

-

Faster installation with reduced labour and handling requirements

-

Enhanced crack control and ductility

-

Lower carbon footprint by reducing steel usage

At Hills Quarry Products, we work closely with leading suppliers of both steel and synthetic macro fibres. Our team can advise on the best macro fibre type for your needs, whether synthetic for corrosion-sensitive environments or steel for projects requiring maximum load performance.

Discuss your specialist concrete solution with us today

Get in touch with Hills Quarry Products to discuss your specialist concrete solution.